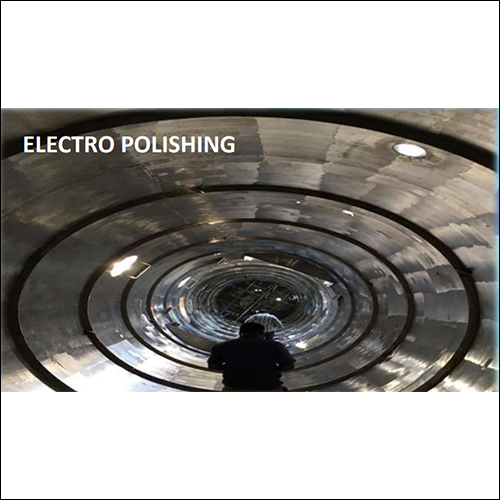

Electro Polishing Service

100000.00 - 1000000.00 INR

Product Details:

X

Electro Polishing Service Price And Quantity

- 100000.00 - 1000000.00 INR

- 1 Unit

Electro Polishing Service Trade Information

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 100 Unit Per Day

- 1 Week

- Standard Packaging

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

Our organization falls under the category of reputed enterprise engaged in providing to the clients. The provided service process smooths and streamlines the microscopic surface of a metal object as a result the surface of a metal object. Our skilled team of professionals undertake the entire electropolishing work and use only quality-approved raw materials and modern plating methodology while rendering this services.

Superior Surface Cleaning and Finish

Our electro polishing service effectively removes surface imperfections, including scales, discoloration, and embedded contaminants, resulting in a flawless finish. With state-of-the-art equipment, we achieve both mirror and satin-smooth surfaces that elevate the appearance and performance of stainless steel components.

Customizable Process for Varied Applications

We offer flexible operational parameters such as current, temperature, and electrolyte composition to meet customer-specific requirements. Whether for the pharmaceutical, medical, food & beverage, or marine sectors, our service is engineered for optimal performance and reliability across diverse industrial applications.

Certified and Environmentally Compliant Operation

Safety and environmental responsibility are at the core of our process. Our certified staff employ PPE and work in controlled settings, while all waste treatment complies with local regulations. We provide inspection and verification, including visual checks and surface roughness profilometry, to ensure high-quality outcomes.

FAQs of Electro Polishing Service:

Q: How does the electro polishing process work for stainless steel?

A: Electro polishing is an electrochemical process that removes surface material from stainless steel components by passing a controlled current (typically 550 A/dm) through them in a sulfuric and phosphoric acid electrolyte solution. This smooths the surface, eliminates contaminants, and produces a highly reflective or satin finish.Q: What kind of contaminants and imperfections can electro polishing remove?

A: This service is highly effective at eliminating scales, discoloration, and embedded contaminants from metal surfaces. It also smooths out micro-roughness to achieve a surface roughness (Ra) as low as 0.08 m, resulting in a uniform, corrosion-resistant finish.Q: When can I expect the electro polished components to be ready?

A: Lead time for our electro polishing service ranges from 3 to 7 working days, depending on the size and complexity of the job as well as any specific customization needs you may have.Q: Where can the service be provided, and what industries do you serve?

A: We offer both on-site and off-site electro polishing services throughout India. Our solutions cater to a variety of sectors, including industrial, pharmaceutical, food & beverage, medical, and marine industries.Q: What inspection and quality assurance methods are used?

A: Each polished component undergoes visual inspection and surface roughness measurement using profilometry. We also ensure that all processes meet industry standards such as ASTM B912 and ASTM E1558.Q: How is environmental compliance managed for this service?

A: All waste generated during the electro polishing process is treated according to local environmental regulations, ensuring environmentally responsible operations and handling.Q: What are the main benefits of electro polishing for my components?

A: Electro polishing enhances corrosion resistance, creates a highly smooth and clean surface, and improves both the aesthetic and functional qualities of stainless steel components, making them ideal for critical applications in demanding industries.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Polishing Service' category

|

PRIME ADVANCE POLISHING SYSTEM PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |