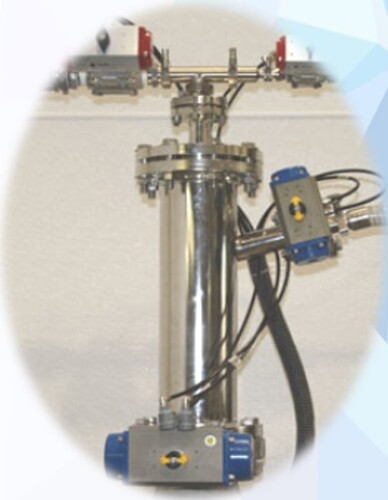

SS and MS Storage Silo

Product Details:

- Product Type Silos

- Material Steel

- Finish Galvanized

- Color Silver

- Bottom Type Cylinderical

- Usage Commercial

- Application Industrial

- Click to View more

SS and MS Storage Silo Price And Quantity

- 1 Unit

- 10000 INR/Unit

SS and MS Storage Silo Product Specifications

- Silos

- Commercial

- Steel

- Silver

- Galvanized

- Cylinderical

- Industrial

SS and MS Storage Silo Trade Information

- Vadodara

- Cash Advance (CA), Cash in Advance (CID), Cheque

- 100 Unit Per Month

- 7 Days

- Standard Packaging

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

Product Description

Storage silos, whether made from Stainless Steel (SS) or Mild Steel (MS), are large containers used to store bulk materials like grains, powders, liquids, or other industrial products. The materials of construction (SS or MS) can affect their strength, corrosion resistance, and longevity.

Heres what typically SS (Stainless Steel) and MS (Mild Steel) storage silos contain:

1. SS (Stainless Steel) Storage Silo:

Stainless steel is commonly used for storage silos in industries where resistance to corrosion, high hygiene standards, and durability are required. These can include food, pharmaceuticals, chemicals, and some heavy-duty applications.

Contents of SS Storage Silo:

- Bulk Materials: Can store powders, pellets, grains, cement, chemicals, or other granular materials. The specific contents depend on the application.

- Liquid Storage: In some cases, SS silos are also used to store liquids like oil, milk, or chemicals, especially in the food, beverage, and pharmaceutical industries, where sanitation is critical.

- Air or Gas: Some silos may store gases or maintain air pressure for pneumatic conveying systems, particularly in processes like cement manufacturing.

Common Applications:

- Food Industry: Grain, sugar, salt, flour, etc.

- Pharmaceuticals: Active ingredients, excipients, etc.

- Chemical Industry: Bulk chemicals, powders, or even liquids.

- Beverage Industry: Ingredients like sugar, malt, and liquid storage for brewing.

2. MS (Mild Steel) Storage Silo:

Mild steel is a more cost-effective material compared to stainless steel, and it is commonly used in industries where the stored material is not prone to corrosion or where the material of construction is less critical. These silos are typically used for storing non-corrosive materials or for applications where cost reduction is a priority.

Contents of MS Storage Silo:

- Bulk Materials: Like grains, powders (e.g., cement, sand, coal), animal feed, or fertilizers.

- Solid Raw Materials: MS silos are widely used to store solid materials in bulk, such as plastics, minerals, and other solid substances in industrial settings.

- Coal and Aggregates: Common in the mining and energy industries for the storage of fuel or raw materials.

- Non-Corrosive Liquids: In some cases, mild steel silos are used for storing non-corrosive liquids, though they are less common in such applications compared to stainless steel or coated steel silos.

Common Applications:

- Cement and Building Materials: Storage of cement, lime, sand, or aggregates.

- Food and Agriculture: Bulk storage of animal feed, grains, seeds, etc.

- Industrial Manufacturing: For raw materials like plastic pellets or chemicals that are not corrosive.

Key Differences:

- Corrosion Resistance: SS silos are more resistant to rust and corrosion than MS silos, making them better for storing materials that may react with steel or need to meet sanitary requirements (e.g., food, pharmaceutical products).

- Durability: SS silos are more durable and can withstand harsher environments, whereas MS silos, while strong, may require additional coatings (like galvanizing or painting) to prevent corrosion.

- Cost: MS silos are generally less expensive to manufacture than SS silos, making them a more cost-effective option for less critical applications.

In summary, both SS and MS storage silos are used to store a wide range of materials, but the choice between stainless steel and mild steel depends on factors such as corrosion resistance, strength, cost, and the type of material being stored.

Durable and Efficient Design

Our storage silos are engineered for maximum durability and efficiency, providing industrial-grade solutions for commercial applications.

High-Quality Galvanized Steel

Crafted from top-grade galvanized steel, these silos ensure excellent corrosion resistance and long-lasting performance.

FAQs of SS and MS Storage Silo:

Q: How is this storage silo beneficial for commercial use?

A: This storage silo is beneficial for commercial use because it provides a secure and durable solution for storing industrial materials efficiently.Q: What materials can be stored in the silo?

A: The silo can store a wide range of materials, including grains, chemicals, and industrial raw products, while maintaining their quality.Q: When should one opt for an SS or MS storage silo?

A: One should opt for an SS or MS storage silo when needing a durable, large-scale storage solution that is resistant to corrosion and built for industrial applications.Q: Where can these silos be installed?

A: These silos are suitable for installation in industrial facilities, warehouses, and commercial storage spaces.Q: What is the process of manufacturing these silos?

A: The manufacturing process includes precision fabricating using high-quality galvanized steel and assembling components in adherence to industrial standards.Q: What are the usage guidelines for these silos?

A: Usage guidelines typically recommend that the silo be installed on a stable base, used for dry or stable materials, and regular maintenance be conducted to ensure longevity.Q: What is the main benefit of using a galvanized steel silo?

A: The main benefit is its excellent resistance to corrosion and rust, making it an ideal choice for long-term durable storage solutions in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Storage Silo' category

|

PRIME ADVANCE POLISHING SYSTEM PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |